|

Photo © Deck Higgins/Deck Higgins Photography |

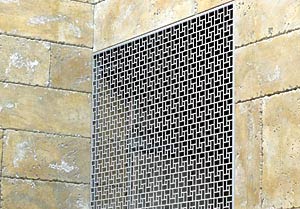

Construction firm’s New Jersey headquarters is a showcase for artisan concrete The new, 50,000-square-foot Rockaway, New Jersey, headquarters for Mackenzie Keck Construction — a provider of contracting, construction management, and consulting services for upscale retailers and other companies — is an adaptive reuse of an ice-cream distribution facility. The New York City—based design/architecture firm Pompei A.D. designed the building’s exterior and consulted on the interior of the project, which is intended to serve as a showroom for the craftsmanship, detailing, and custom design work for which Mackenzie Keck is renowned. As part of that goal, the headquarters features custom handcrafted concrete by Concrete Design Studios (CDS), an affiliated company. Custom concrete was applied in the project both decoratively and structurally. For the headquarters’ lobby, CDS replicated approximately 200 versions of a 2' x 12' stone slab in order to create the walls for the building’s central stairwell. “The beauty was that I was able to do that for a third of what natural stone costs,” says Dan Keck, C.E.O. of Mackenzie Keck. An exterior wood-curtain-wall system constructed from European Oak timbers (a prototype being tested for future distribution in North America through Mackenzie Keck) sits on custom-fabricated concrete sill stones cantilevered over the adjacent structure. Other features by CDS include leatherlike concrete panels that frame the entrance and lobby, concrete bathroom sinks and tiles, and a table inspired by the ice-cream machines that once occupied the space. As part of CDS’s sustainable practices, fresh water is used only for batching the concrete, while the polishing and cleaning of mixers is done with water recycled on-site, a technique that cuts down water consumption by 95 percent. All of the sand and gravel used to make the concrete is obtained in quarries within 70 miles of the new headquarters, and fly ash and silica fume are used as cement replacement. The resulting product is a lightweight, yet highly durable concrete (ranging from 12,000 to 45,000 psi) that can be used in locations where heavier fabrications are not an option. CDS can also mix concrete in 54,000 different colors and store these recipes in its computerized system for future use. While Keck says the company is in better shape than most, 2009 appears to be the first year since the company was founded in 1990 that it will not have done more business than the previous year. “The reality is, we are seeing about a 15 to 18 percent slowdown in volume.” Mackenzie Keck/Concrete Design Studios, Rockaway, N.J. www.mackenziekeck.com [Reader Service: March 2009 #210] |

|

Creative concrete [Reader Service: March 2009 #211] |

|

Stone puzzle [Reader Service: March 2009 #212] |

Post a comment to this article

Report Abusive Comment